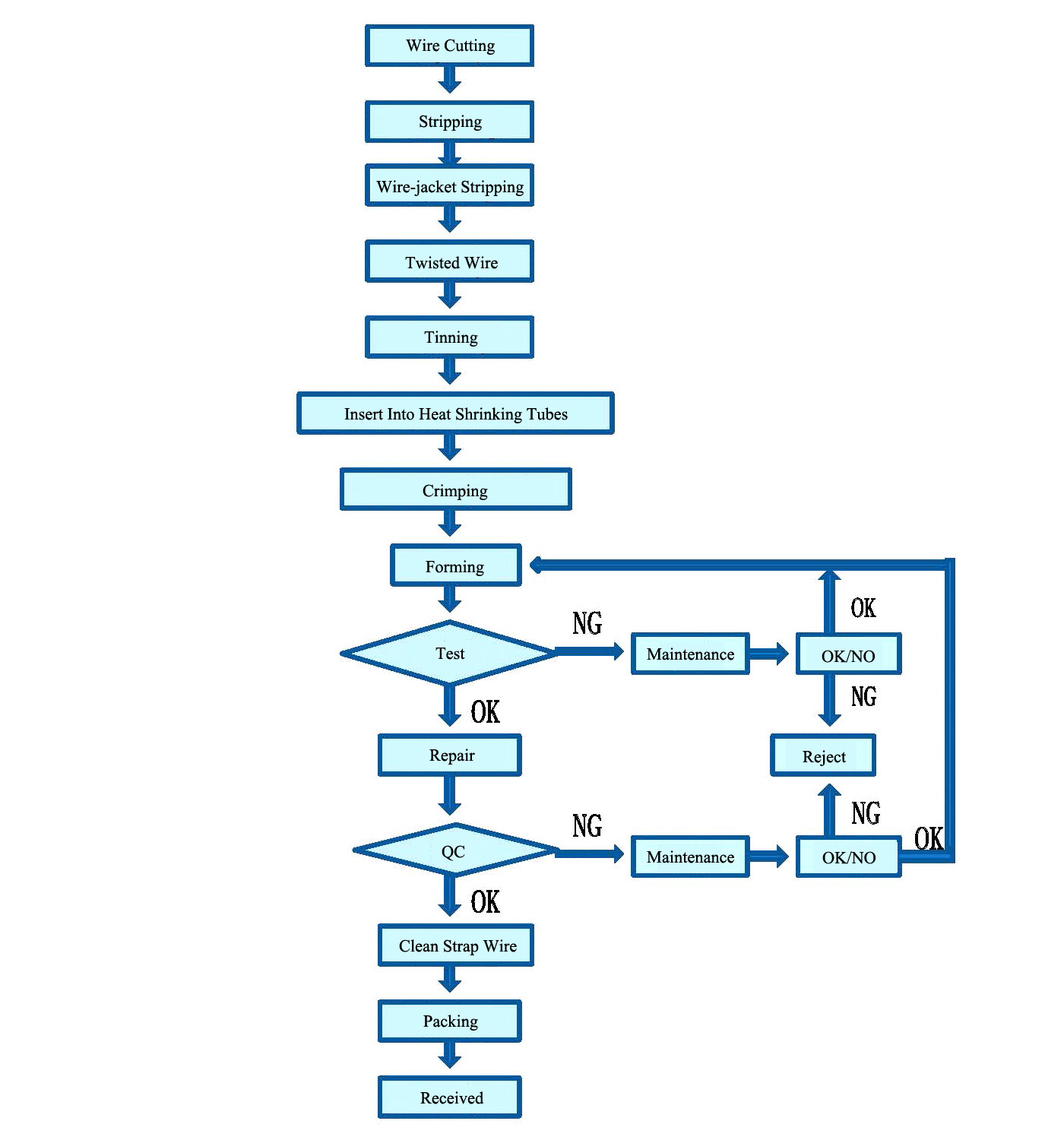

Wiring Harness Process Flow Chart

You get hired at a large oem to design electrical wiring harnesses and wired box assemblies. Process flow chart quality tool it is far more helpful as a reference guide if anyone wants to know about the home’s electrical system.

PROCESS FLOW CHART CHEMICAL ENGINEERING Auto Electrical

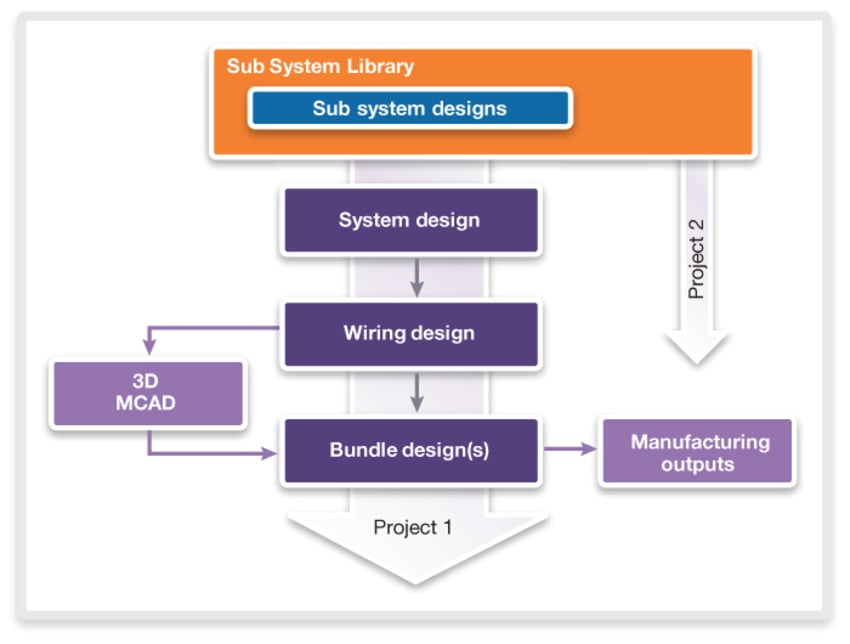

First, the wire harness specifications are drawn up in the same way we would diagram the play.

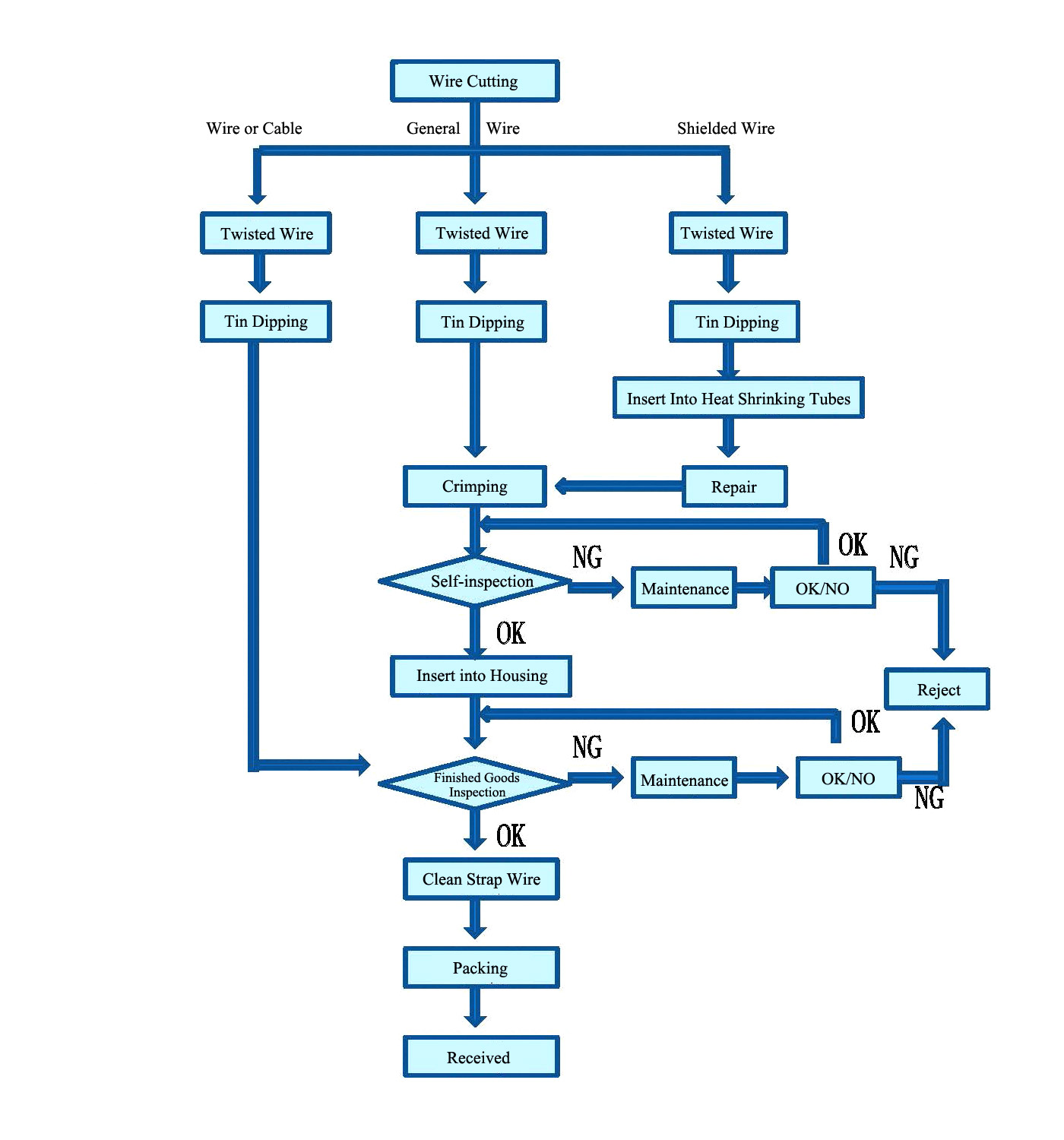

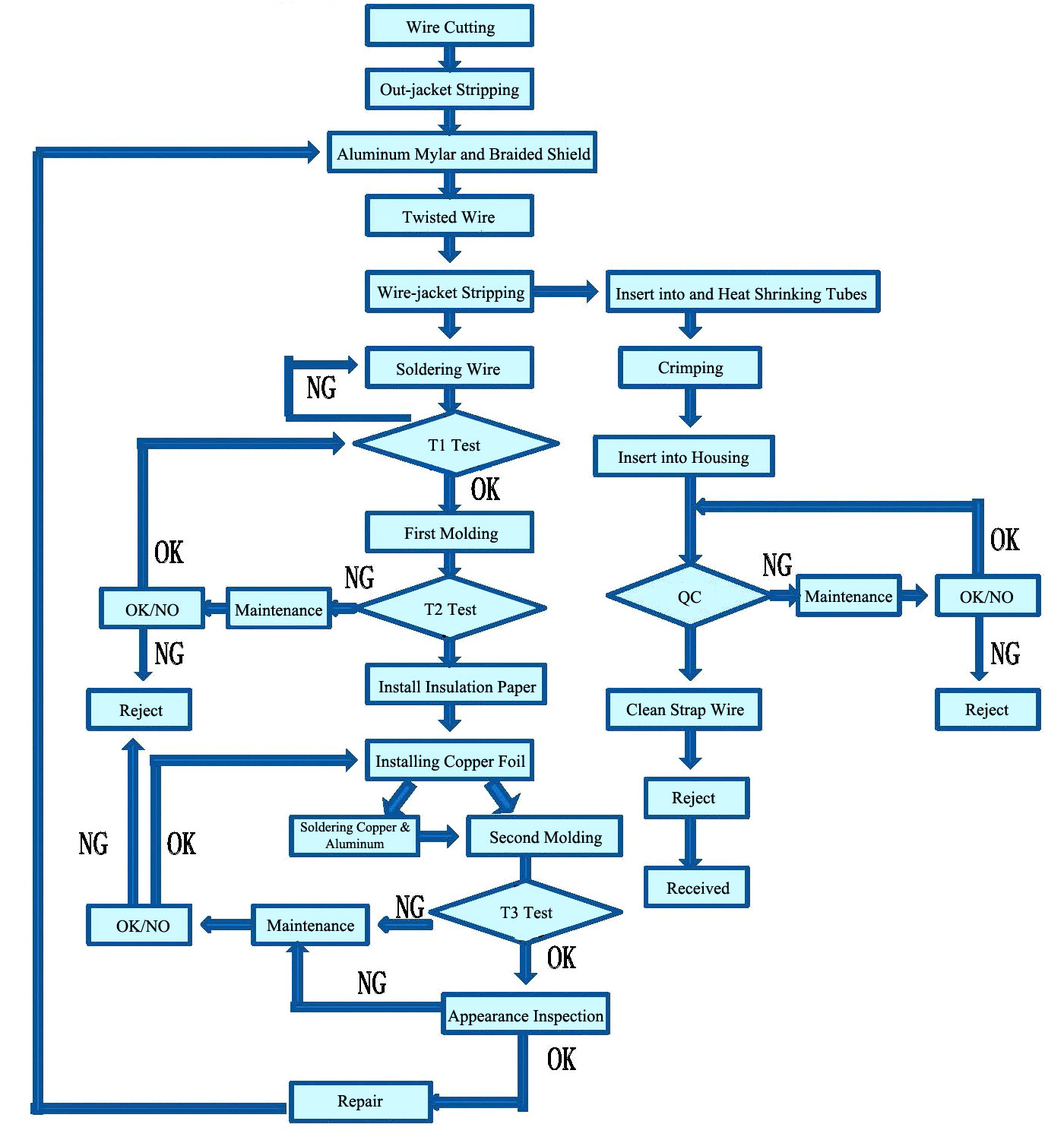

Wiring harness process flow chart. Wiring harnesses connect all electric and electronic components in a vehicle, enabling the communication and information flow as well as their energy provision. The manufacturing process for wire harnesses can go from basic to very complex. Nonetheless, as the demand for wire harnesses and cable assemblies grow, manufacturing of these components continues to expand.

However, wire harness designing needs to go through certain basic steps and processes. Lean manufacturing concepts helped arrow electronics improve its assembly processes. • did is the process of assigning each warp end to a harness frame.

We are manufacturer of wiring harness process flow chart in china, if you want to buy wiring harness process flow chart, please contact us. Lean six sigma implementation in cable harness manufacturing 55 fig. So, from the above table it is noticed that the manufacturing lead time is 241 minutes or 4 hours,

It uses different line colors to identify what the wire is used for. Read how this cable and wire harness assembler took lean manufacturing to the next level. Learning media development (lmd) subject:

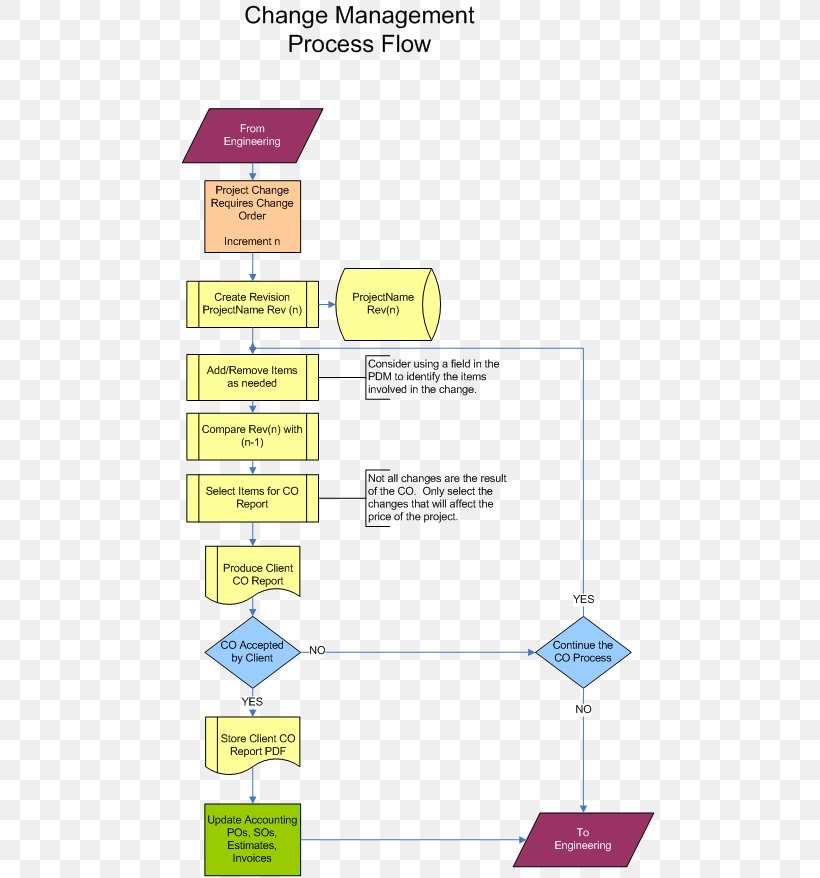

You can tell from the wiring harness diagram how complicated or how pure your custom wire harness would be. We are requested to submit process flow diagram, contol plan and pfmea. What you will have is a further engaged target market and the go with the go.

It’s only through this the effective functioning of the application can be ensured. The cables are bound together by straps, cable ties, cable lacing, sleeves, electrical tape, conduit, a weave of extruded string, or a combination thereof. Is the least efficient diagram among the electrical wiring diagram.

Not having the proper training in college you ask yourself, “where do i start?”. Hello all, our customer is a tier 1 supplier to chrysler. Thank you for your comments.

Modern vehicles come equipped with an almost dizzying array of electronic features and components. •during the wiring harness design process, there are thousands of different part numbers to select from. The vital few causes for wire contact crimp height variation had been identified to include;

The wires are stripped and cut at the right length. The harness diagram will help you create an exact plan of how all the wires and connectors will be put together. 1.26 process flow chart for cable harness manufacturing reliability of the system.

There’s a lot more to the process of course, and thankfully, the wire harnesses usually don’t talk back to us. Time taken for different processes. • the vertical columns in the did represent the warp threads and the horizontal rows represent the harnesses frames which are numbered sequentially from bottom to top.

For example, colored circles can symbolize connectors. 3.5 1.35mm dc power cord cable for wiring harness. Free download popular latest flowchart process flowchart workflow bpmn

A harness wiring diagram template shows the wire connection between harnesses. A cable harness, also known as a wire harness, cable assembly, wiring assembly or wiring loom, is an assembly of cables or wires which transmit signals or electrical power. So let me guide you with some electrical wire harness design basics.

The wire harness manufacturing process is time consuming, difficult, and task oriented. Then, the harness is meticulously laid out, just as we demonstrated to the kids how to execute the play. Ideally, every cable harness circuit diagram will have the following;

Wiring harness, coupler & terminals, relay & junction box, steering roll connector injection molding, 2k molding process : Last edited by a moderator: Kinematic component & premium surfaces, garnish & trims, dashboard, consoles, parcel shelf, air vent, air duct, ash tray, arm rests, cup holder

Symbolized components, optimum positioning, splice positions and wire colors. Process flow diagram examples visio it is far more helpful as a reference guide if anyone wants to know about the home’s electrical system. The process flow chart is fig.

You can also color the diagram to represent different parts. Does anyone have an example of a wiring harness. Process flow chart and pfmea have been used to assess current control and prevention measures.

Its components are shown by the pictorial to be easily identifiable. That’s because the wire harness is one of the most indispensable electronic and electrical components in the modern world! The next step usually involves wire cutting, stripping, and terminating.

This will help you to keep things organized, and make the process easier. It starts with the design process and making sure that the harness incorporates any necessary custom features for its intended application. Creating a wire harness with harness design author:

Patent US6438435 Apparatus for processing information of

PROCESS FLOW CHART CHEMICAL ENGINEERING Auto Electrical

Wiring Harness Manufacturing Process Flow Chart Best

PROCESS FLOW CHART CHEMICAL ENGINEERING Auto Electrical

28 Health Insurance Claims Process Flow Diagram Wiring

Wiring Harness Manufacturing Process Flow Chart Wiring

7step process for aircraft wire size and circuit

[WX_3968] Fabrication Process Flow Diagram Download Diagram

[TM_6599] Chemical Process Flow Diagram Symbols Free Diagram

Process Flow Diagram Library flow chart

Wiring Harness Process Flow Chart Wiring Schematic

[ME_2972] Process Flow Diagram Ts 16949 Schematic Wiring

What use is an Application Programming Interface (API) in

Flow Diagram Car Manufacturing Process Flow Chart

Process Flow Diagram Manufacturing Diagram Media

Patent US6438435 Apparatus for processing information of